Machine safety

Manufacturers seeking efficiency improvements often overlook the impact of machinery safety issues.

Achieving workforce safety and continuity of production performance as a result of machine risk assessments and upgrades to safety technology for greater machine consistency delivers increased OEE. More and more manufacturers are adopting a plant floor approach to safety to reach these objectives.

Applying years of machine safety engineering expertise in manufacturing, we help your company reach its safety program goals by meeting you where you are. You have made significant investments in both your people and plant assets. We will help you protect your assets and your productivity. Our Safety Practice leads hold certifications in global safety competency as Functional Safety engineer – TÜV Rheinland and Certified Machine Safety Expert – CMSE® – TÜV NORD. These certifications validate that your safety projects will be delivered with proven competency and expertise in best-in-class machine safety practices and thorough understanding of safety standards. Polytron’s machine safety experts were among the first in the industry in Rockwell Automation’s Machine Safety Integrator Program.

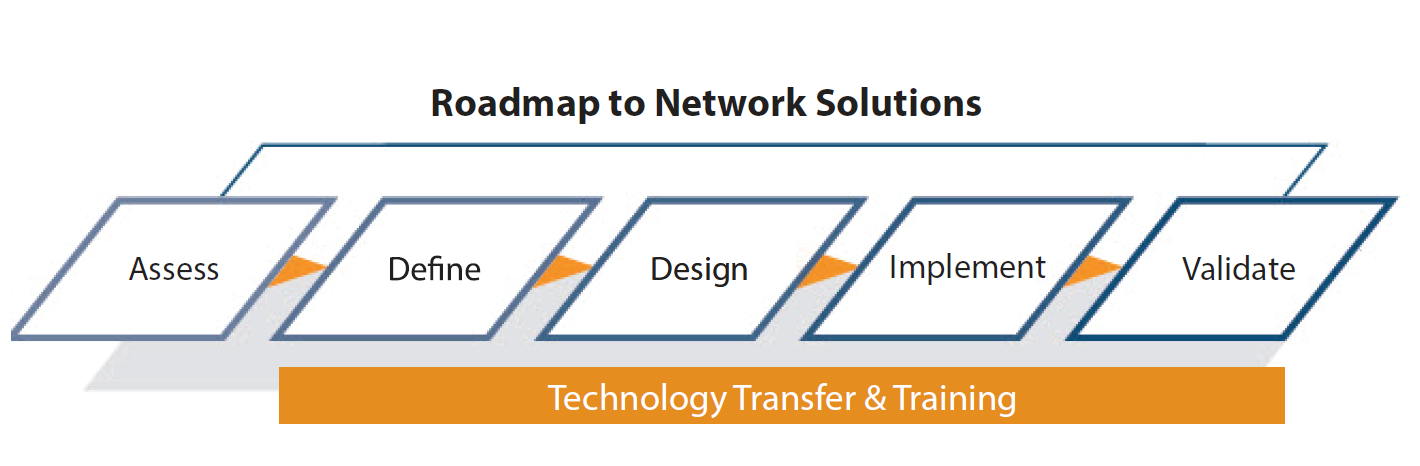

Polytron’s methodology and approach to every machine safety project begins with a thorough plan. The diagram below outlines our approach to reach a safe machine state.

- Regulatory and Corporate Safety Standards: We apply safety standards as the foundation for every decision and step in the process.

- Risk Assessment: By conducting a risk assessment or safety audit, we identify the hazards and the risk level of each hazard.

- Definition: Using the results of the risk assessment, Polytron creates a definition of how to address each hazard.

- Design: A detailed safety design is created to provide a functional design spec, hardware/software requirements, installation bids, and final scope, schedule, and cost for the safety solution to mitigate each hazard.

- Implement: Once approved, the solution is implemented on your equipment.

- Validation: The solution is validated to ensure that it meets the design specification, regulatory and company safety standards.

- Training: A machine safety project typically makes operational changes to the equipment. This requires that operators, maintenance and technical staff must be re-trained for the safe operation of the newly updated equipment.