SOLUTIONS AND SERVICES

Polytron guides our clients by first clarifying their challenges and goals. Then, define, design and deploy the best solution and technology for their business, delivering certainty in outcome.

Manufacturers experience challenges to reach business objectives and goals. Finding the adequate bandwidth across existing engineering staff for large project; prioritizing the path forward; identifying gaps in the required knowledge and expertise to move projects to completion; and the lack of internal resources to provide guidance to get started.

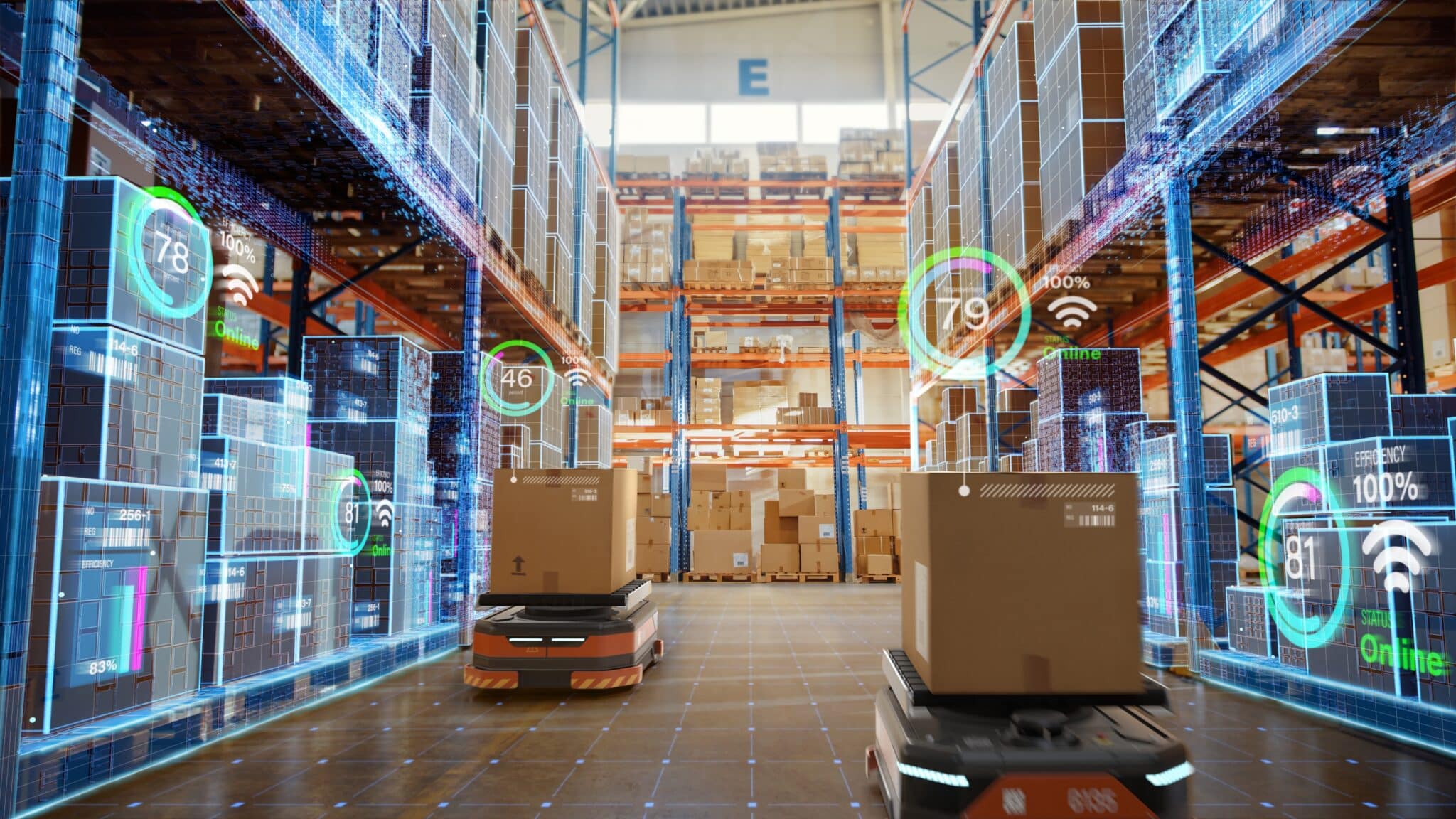

Smarter solutions and decisions come from unleashing the power of data from your plant floor to enable you to start the Smart Manufacturing journey for improved efficiency and increased profitability.

Packaging

Expanding production capability includes the need for new packaging lines or an upgrade of existing lines. Making decisions on the right options and solutions to achieve the objectives often leaves the manufacturer wondering how to begin and how to do it all on their own – on time and within budget. By offering Packaging Turnkey Solutions from concept to virtual commissioning, implementation, and technology transfer, we help you expand capability from beginning to end with options and solutions designed for your specific business drivers.

Smart Manufacturing - MES/MOM

Smarter solutions unleash the power of the data from your plant floor to enable you to start the Smart Manufacturing journey for improved efficiency and increased profitability. Identifying and implementing the right technology, process, and organizational changes required to leverage that data delivers the highest value. Data-driven projects can produce a quick return and influence – even reduce – critical capital expenditure projects.

Process

Your manufacturing process system is more than just pipes, pumps, tanks and valves. It is the heart of your operation providing recipe management, batch control, and uncompromising product quality. Today’s market demands flexibility for consumer-driven products with high yield, sustainable OEE, ease of operation, expanded and updated batch capabilities. Smart control systems, data visibility and the ability to respond quickly are the keys to maintaining your competitive positioning in the industry.

Industrial Network and Security

Developing a robust and secure network infrastructure requires protecting the integrity, availability and security of manufacturing control data. Our approach to industrial network convergence applies a design methodology for your network requirements to develop a physical framework to align to support your Smart Manufacturing strategy. Our roadmap ensures secure, standardized, and consistent network integration to enable plant and enterprise-wide information sharing.

Project Management

Many manufacturers are overwhelmed with the amount of effort, level of detail, or expertise required to successfully complete capital projects and ensure the investment meets their company’s goals. A proven, disciplined approach to project execution coupled with over 35 years of experience deploying process and packaging systems will lower your risk while ensuring your company’s future success. And building these systems with Smart Manufacturing technologies can be achieved with innovative expertise along with a roadmap for successful delivery.

Automation and Controls

Manufacturers are upgrading out-of-date automation and control systems to improve efficiency and operational performance to meet your business objectives of increased production output and quality to achieve growth targets and remain competitive.

Machinery Safety

Manufacturers seeking efficiency improvements often overlook the impact of machinery safety issues. Achieving workforce safety and continuity of production performance as a result of machinery risk assessments and upgrades to safety technology for greater machine consistency delivers increased OEE.

“Things are more automated now. It can get really complicated. You really need someone who understands the deep details of how our system works. Polytron has that expertise. They save us money by not having to start the process over each time. They know our business.”

– BEVERAGE MANUFACTURER