Polytron helped a large grocery store chain modernize its aging flour silos at its baking facility by relocating and upgrading it’s flour delivery control system. Through meticulously planning a multiphase approach, Polytron provided the grocery store chain with a modular, forward-looking control system that helped reduce the growing risk of operational downtime while allowing them to easily make adjustments for future needs.

Challenge |

Solution |

Results |

| When a large grocery store chain needed to replace the aging flour silos at its baking facility, they realized they also needed to relocate and upgrade the control system responsible for managing flour delivery without shutting down operations. | By meticulously planning a multiphase approach, Polytron strategically relocated and upgraded the flour delivery control system while seamlessly integrating it with existing systems to keep the bakery running as the necessary upgrades were made. | By upgrading the flour delivery control system, we provided this customer with a modular, forward-looking control system that helped reduce the growing risk of operational downtime while allowing them to easily make adjustments for future needs. |

The Project

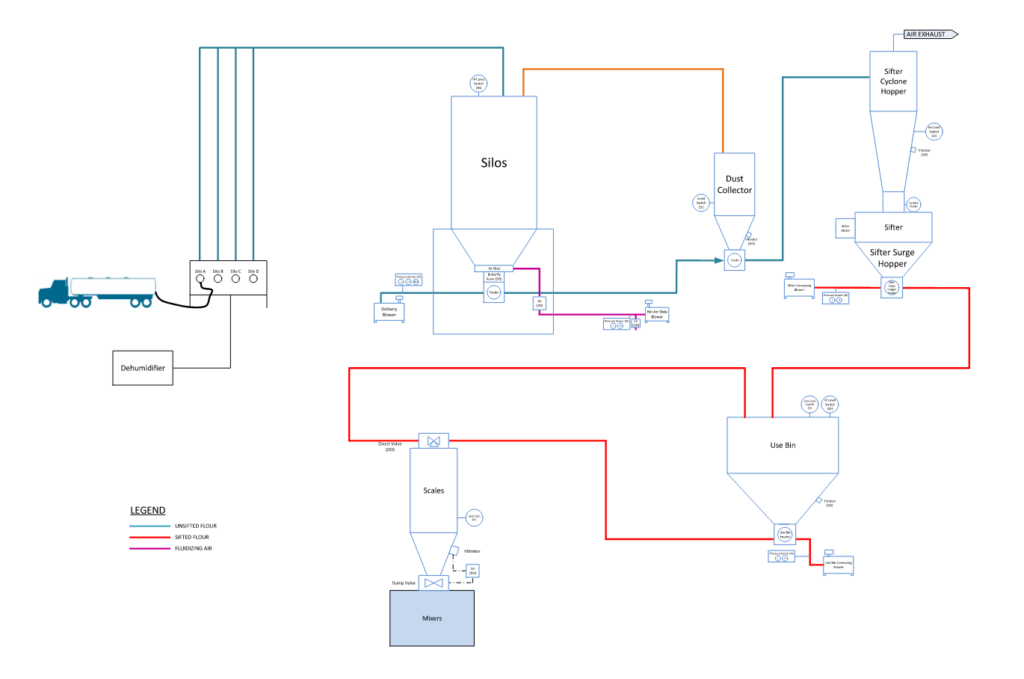

When mass producing fresh bread and flour tortillas for a few hundred grocery stores, you need large quantities of flour constantly on hand. For one of the nation’s largest grocery store chains operating its own bakery, flour was made readily available via four large silos located on the exterior of their facility (Figure 1). This critical ingredient is received into the silos from delivery trucks, stored in the silos, and then pneumatically conveyed to an industrial sifter before being delivered to one of six mixers or the flour dusting system.As two of the flour silos started to age, the company realized it not only needed to replace the silos, but they also needed to relocate and upgrade the control system responsible for their flour delivery process. In addition to facing obsolescence issues, the control system was also housed in the skirt of one of the silos that needed to be replaced, which meant the silo could not be decommissioned with the control system located there.

Since this company had worked with us on a smart manufacturing project at one of their snack plants a few years earlier, they asked our team to put together a conceptual project plan outlining the scope, cost, and schedule for what this work would entail. As we worked to clearly understand their needs and the interdependencies of the flour delivery system, the plan took shape and included:

- Developing a new more modern and modular control system

- Locating the new control system in an accessible point inside the building while still maintaining connectivity with the flour silos and parts of the existing control system

- Updating the sifter room controls and HMI and relocating this equipment outside the sifter room

- Replacing additional hardware identified as obsolete

- Performing mechanical and electrical demolition, relocation, and installation of piping, blowers, valves, control panels, and field devices

Once the conceptual project plan was completed, funding was approved for the project and the client moved forward, working with our team for the full execution of the project. Our scope included project management, detailed mechanical and electrical engineering, PLC and HMI programming utilizing Rockwell Automation’s PlantPAx, mechanical and electrical construction, and onsite startup support.

Our Process

Meticulously Planning a Multiphase Upgrade to Minimize Downtime

Since this bakery produces fresh products with a short shelf life, they cannot build inventory to allow for a major outage for upgrades, making the need for minimal downtime a key requirement. Therefore, we decided to approach this project in three main phases aligned to the different areas of their flour delivery process, which included:

- Unloading flour from trucks to the silos and delivering flour to the sifter room

- Processing flour in the sifter room

- Delivering flour from the sifter room to the mixers.

As part of this phased upgrade approach, we had to develop a plan to strategically integrate the new control system with the existing systems since production could not be taken down to perform all the upgrades at one time. In this plan, we detailed how we would replace hardware for one part of the process while keeping the old control system temporarily functioning so production would not be interrupted.

Taking this approach meant we had to develop a thorough understanding of the existing hardware to verify how it would interact with the new system. For example, we determined we could replace an existing PLC with an Ethernet communication module to keep the existing I/O intact, which shortened downtime for the first phase of the project.

We also utilized DeltaV Mimic Simulation Software to build a model of the flour delivery system and tied it directly to our PLC program and HMI. This allowed us to complete emulation testing prior to the onsite execution of each phase, saving time and reducing risk.

Prior to starting the upgrades, we further divided the three execution phases to keep downtime to a minimum. For Phase 1, flour delivery to the silos and from silos to the sifter room, we upgraded two of the four silos at a time. When we upgraded silos 1 and 2, the plant could run using silos 3 and 4. Once silos 1 and 2 were complete and commissioned, the plant ran using silos 1 and 2 while we upgraded silos 3 and 4. At the end of phase 1, the plant was running off the four silos using the new control system.

Phase 2 of the project involved upgrading the delivery of flour from the sifter room to the six mixers and a flour dusting system. Since the plant could not take down all the mixers at one time, we further divided Phase 2 into five sub-phases, which allowed us to only take down one or two mixers in each phase.

Phase 3 involved upgrades to the existing sifter room, including replacing motors and controls for the room with a panel mounted outside of the room. This allowed operations access to control the devices without entering the room. A flow diagram for the new system is shown in Figure 2.

Across these phases, to further minimize downtime, we performed as much pre-work as possible. This involved tasks such as installing the new control panels, running conduit and conductors from the control panels to field devices, and installing network connections all before taking the system offline.

Reliable Flour Flow, Reduced Downtime

A key objective for these upgrades was to reduce the risk of operational downtime, which was accomplished by removing obsolete hardware from the system and providing the facility with a more modern control system. We also programmed the HMIs using the company’s existing standards based on PlantPAx. Not only did this allow for continuity across multiple systems, it also greatly reduced the time needed for operator and maintenance personnel training since they were already familiar with these standards.

Simplifying Future Changes with a Forward-Looking Control Architecture

After we completed this project, we were involved in a subsequent project to replace two of the customer’s silos with one new silo, a project that was enabled by the controls upgrade project. During the original project, we implemented a modular control system architecture, with the main control panel located inside the facility and POINT I/O panels in each silo that communicate to the main PLC over Ethernet. This modular design makes it easy to scale up or down, so when we demoed these next two silos, we could easily disconnect the silos and then repurpose one of the POINT I/O panels for the new silo.