Efficient, Effective, Profitable Production with MES that Works

Polytron’s smart manufacturing solutions streamline manufacturing operations – from production scheduling and inventory management to quality control, maintenance, and beyond.

Polytron’s certified and award-winning Smart Manufacturing Group partners with manufacturers to address complex business challenges. We leverage best practices, proven solutions and best-in-class technologies based on our 20+ years helping manufacturers achieve their goals.

Learn how a food and beverage company achieved a 20% improvement in OEE with Polytron’s TrakSYS implementation.

TrakSYSTM MES at the core

One platform, multiple impacts

Inventory

Optimize the flow of goods to reduce working capital requirements, manage lead times, avoid production disruptions, and improve on-time.

Production

Factor in order volume, inventory levels, asset capacity and utilization, downtimes, and more to keep you on track - no matter what.

Quality

Eliminate the high cost of poor quality by empowering teams with clear instructions, timely notifications, and meaningful information.

Maintenance

Gain real-time metrics for machine run times, performance, historical trends, and maintenance records to help prevent equipment breakdowns.

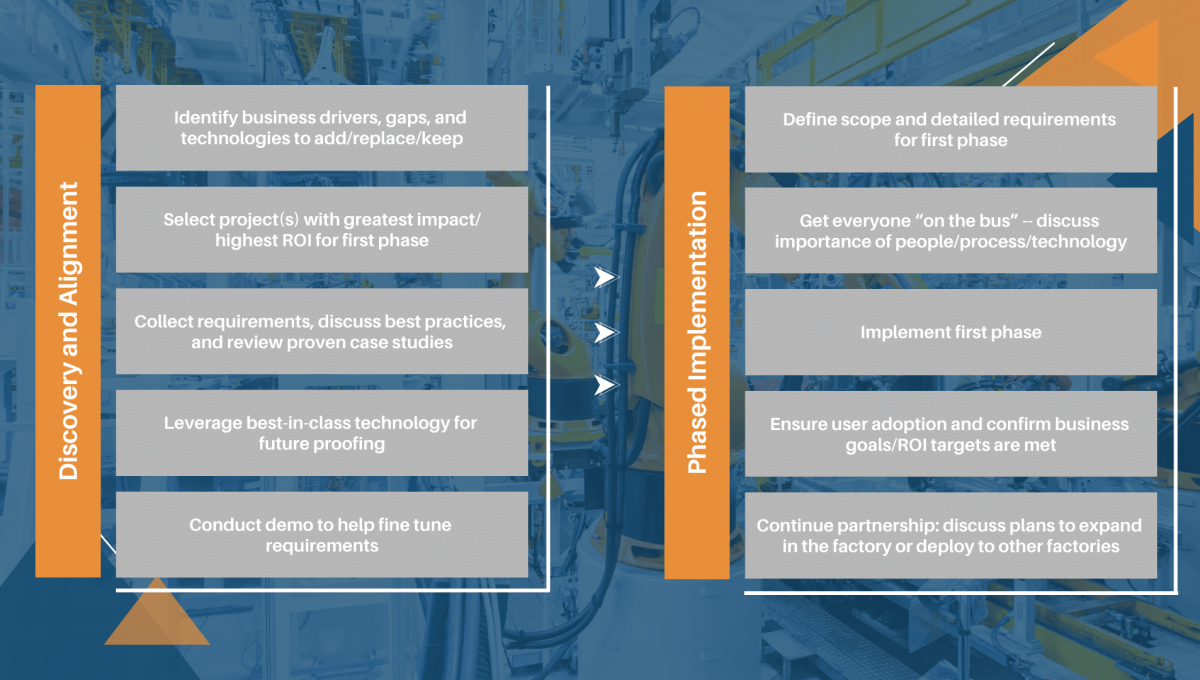

Polytron's proven approach to a successful

smart manufacturing strategy

Making manufacturing operations management as simple as possible

Scalable

Gain a versatile, extensible, and technologically advanced solution.

Smart

Capture real-time production data and

cut total costs with

new efficiencies.

Safe

Improve working conditions, and reduce environmental

damage.

Successful

Achieve greater

visibility, knowledge,

and control to

boost output.

Smart Manufacturing with TrakSYSTM

Typical solutions

Here are some of the solutions we deploy

- Historian

- Recipe Management

- Production Scheduling

- ERP Integration

- Algorithmic Production Scheduling

- Track & Trace

- Performance Tracking

- Quality Management

- Production Tracking

- Material Resource Planning

- Production Labor Tracking

- Simple Warehouse Management

- Maintenance Management

- Predictive Maintenance

- Inventory Management

- Visual Workflow

- Energy Management

- Centerlining

- Electronic Journal

- Task Management

- Reporting

- Dashboards

- Scoreboards

- Mobility

-

loT Mesh Enabled Sensors

(Digital & Analog) - Supply Chain Integration

- Integration with almost any other system

- Industry 4.0 technologies:

- Machine Learning

- Block Chain

- IIoT

- Cloud

- Smart Glasses

- Cobots

- AMRs

Network. Share. Learn.

Get in touch with us

3097 Satellite Boulevard Building 700, Suite 200 Duluth, GA 30096

(855) 794-7659

Follow us

Polytron, Inc. Resources

White Paper

Learn how to leverage a proven MES platform to develop and deploy a digital transformation strategy that uses a phased implementation approach.

CASE STUDY

WEBINAR

CASE STUDY

WEBINAR

CASE STUDY